Holistic energy solutions from Linde Material Handling

The right energy system

To rise to the business challenges of the future, you need to optimise how you use your energy today. That is why more and more companies are asking which energy system will best enable them to square productivity with environmental protection. The motto in intralogistics is: Maximise efficiency, reduce costs, increase sustainability.

From our many years of experience, we know that the “one size fits all” does not work. That is why we at Linde offer a comprehensive portfolio of different drives, batteries, chargers, and software tools, and tailor them to your individual goals. We provide expert consulting services to ensure that individual factors such as fleet size, network infrastructure, work processes, and production targets are taken into account.

Whatever the optimal solution for you is, be it a classic combustion engine, lead-acid battery, lithium-ion drive or fuel cell. With us, you get the best technology for your needs – for maximum performance and sustainability.

With optimal advice for the optimal solution

Every company has different requirements and expectations. That’s why Linde takes a holistic approach to energy consulting. We analyse where you’re starting from, taking into account aspects such as fleet, operations, infrastructure and sustainability goals, and focus on specific requirements rather than individual technologies or products.

We help you to choose the right drive system, support you with resource planning for your trucks, provide a tailor-made design of your energy infrastructure, and optimise your charging cycles. This brings a number of advantages:

- Up to 40% reduction in energy costs

- Optimisation of the availability of your fleet

- Avoidance of power peaks in the power supply

- A simplified charging process for your operators

- Support in achieving your sustainability goals

- Better use of your own energy sources

Energy Quick Check

Use our Energy Quick Check to take stock of your company’s energy systems quickly and easily. Find out which technologies are suitable for your application in just a few clicks. Give it a go now:

Overview of our energy systems

Everything from a single source, everything from Linde

The integration of truck and energy system is a key factor in the energy efficiency and performance of forklift trucks and warehouse handling equipment. That is why we offer pallet trucks and stackers, tow tractors, reach trucks, electric forklift trucks, order pickers, narrow-aisle trucks, tugger trains, and our automated trucks with lead-acid and lithium-ion batteries and the associated chargers from our own development and production. It is also why we developed our own hydrogen technology and now manufacture the drive system for our pallet stackers and trucks, electric forklift trucks, tractors, order pickers and tugger trains with fuel cells.

You can find the right Linde truck for your specific requirements here.

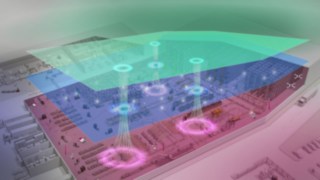

Charge management

The connect:charger from Linde is an intelligent charge management system for electrically powered industrial trucks. It networks multiple chargers to monitor and coordinate current power consumption. The availability of the trucks in the overall process is largely decided at the charging station. However, charging several trucks at the same time can lead to peaks in consumption and thus to high costs. Linde offers an efficient solution with the connect:charger.