The new generation of counterbalance forklift trucks: design insights

Signature move(s)

For decades now, Linde forklift trucks have been distinguished by their design, for which the honour goes to none other than Porsche Engineering. The most recent achievement of this progressive partnership: the new generation of Linde counterbalance forklift trucks X20 – X35 and H20 – H35.

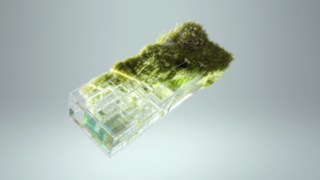

Workhorse or wow factor? Ergonomics or emotion? Function or form? Need or want? Decisions are easy, if you don’t have to make them. And it’s the same for the new generation of Linde counterbalance forklift trucks, the product of a collaboration between Linde and the professional designers at Porsche Engineering. The trucks, which are in many respects groundbreaking, represent a big (red) reconciliation of apparent opposites – and also, coincidentally, resolve an additional problem. From now on, we can state that the X series is the same as the H: for the first time, electric and internal combustion forklift trucks are absolutely equal in terms of performance, efficiency and robustness. This is reflected in the unique design of the trucks.

The tougher the challenge, the greater the draw

It’s quite clear: there are few tasks more challenging than designing a visually appealing forklift truck. The experts from Porsche Engineering can confirm this: “Take cars, by comparison: we usually think cars are attractive if they are wide and have a flat roof line and large wheels. A forklift truck is more or less the opposite of this”, explains Stefan Stark, Designer and Team Leader, who has been in charge of designing Linde industrial trucks at the world-famous engineering company for over 20 years. But this is ultimately precisely the appeal of the task for him: to make a high and narrow truck with small wheels look really good. Quite apart from the fact that the specifications 'high', 'narrow' and 'small wheels' are the least of his problems. As Stark says: “The requirements from the Linde Development Department are usually already very specific, in any case. And those for the current counterbalance forklift trucks were the toughest I can remember over my entire time as product designer for Linde. But that’s what groundbreaking creativity is all about – and it’s often the tougher challenge.”

Mission: Possible

It's a bit like those (un)popular problems in maths exams... If the following are given: length, width, height and turning circle, diverse technical components, position of seat, steering wheel and operator, plus a modular concept for two entirely different energy systems (combustion and electric) in a range of weight classes, how can we find a design for both drive versions that facilitates the best possible performance and provides the operator with an extremely ergonomic workspace combined with Business Class comfort, and with visuals to match. “I must admit, when presented with these specifications, most of us were initially reminded of the Hollywood blockbuster ‘Mission: Impossible’”, Stefan Stark confesses, “but of course in that film the hero always wins out in the end somehow.” And so the designers at Porsche Engineering likewise delved deep into their box of tricks when developing the new Linde counterbalance forklift trucks.

The forklift that grows without growing

One of the numerous ingenious design solutions is immediately apparent at the rear of the truck. Here, the striking grille and the trailer attachment give the forklift a determined look, make it appear much broader and help it to 'stand' with greater stability – even though the truck is not actually any wider. “After all, the paths through warehouses and production halls aren’t getting any bigger”, underlines Stefan Stark. So the designers borrowed a well-known principle from fashion design: horizontal stripes make people – and trucks – look wider. The forklift’s commanding presence is also enhanced by its broad shoulders, emphatic sides, and eye-catching wheel arches, whilst the C-pillar is to some extent 'supported' by the rear wheels. The final touch is supplied by the operator's cab, which has been shifted towards the rear, making the truck appear even more generously proportioned. In automobile design, this effect is known as 'dash to axle'; it describes proportions that are generally perceived as 'premium'. “Overall, we achieved an impression of quality, dynamism and safety by means of the extreme triple-dimensionality of the surfaces. One of our colleagues even thought the rear view resembled the notorious facial expression that Clint Eastwood used to pull; another said it reminded them of the ‘Transformers’. I think both of them are probably spot on”, jokes Stefan Stark.

I'm a technical high performance truck and I make working long and hard a pleasure. I’m premium standard. I'm a Linde.

Welcome to Business Class

We agree that the exterior is somewhat exceptional. But what about the interior? The team at Porsche Engineering are especially proud of the interior design, which is distinguished by both its intelligence and its quality, since it was created with a clear idea in mind: Business Class. The idea is magnificently embodied in a coherent design concept, whereby the operators are 'integrated' into the truck. Stefan Stark: “In many competitor models, the interior is really compartmentalised and disjointed; by contrast, everything in ours ‘flows’ harmoniously into everything else, and gives an impression of uniformity. From the dashboard, which we have carefully designed down to the very last detail, to the armrest, the operator is virtually ‘embraced’; they feel that their every ergonomic requirement has been catered for, and that they have been provided with a workspace that is also simply pleasant and comfortable.” The trucks also feature compartments in practical positions and the extremely generous legroom and headroom that operators have come to expect from Linde. “After all, anyone who has to work in a operator's cab for eight hours or more doesn’t want cramped conditions like those in a fighter jet”, explains Stefan Stark.

The message is clear: it’s a Linde

So you see, you don’t need to perform death-defying stunts to accomplish your mission or solve the unsolvable. In the case of the new Linde counterbalance forklift trucks, the key to success was rather the combination of brains, creativity, experience and productive collaboration. This was the only way to design a generation of forklift trucks that would send out a clear message: “I'm a technical high performance truck and I make working long and hard a pleasure. I’m premium standard. I'm a Linde.”

A strong team, side by side

Porsche has been manufacturing sports cars for more than seven decades. However, the name was first linked to technological innovations much earlier: Ferdinand Porsche founded and registered his design office in Stuttgart on 25 April 1931. The name Porsche has been closely associated with client development projects ever since.

Linde Material Handling and Porsche Engineering have been collaborating for almost 40 years, including on the design of Linde industrial trucks products. The very first collaborative project was the Linde H30 (series 351): a 'styling' project with the aim of taking machinery which was technically revolutionary and setting it stylistically apart from the competition as well, thereby ushering in a new era for the industry. Porsche design has now become a multi-award-winning trademark feature of Linde trucks. Since the start of the collaboration, they have been awarded 25 design prizes.