Solutions Tailored To Your Business

Warehouse Automation

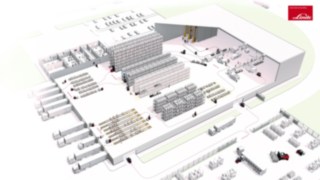

Scalable and cost-efficient warehouse automation is a critical element of an optimal material flow. Automated procedures ensure consistent, efficient and flexible processes. They improve your goods handling times and help minimise personal injury and damage to goods and infrastructure. We provide automated trucks, the latest technology and a comprehensive material flow consulting service to help you fully exploit your economic potential. From delivery through to dispatch, we use our comprehensive understanding of intralogistics to analyse individual process steps or entire material flows. Whether an existing system or new project: the goal of warehouse automation is always to maximise your efficiency gains. Our offer is not just limited to our automated trucks. Together with our partner companies, we provide everything that you need to automate your processes including warehouse software.