Top performance for indoors and outdoors

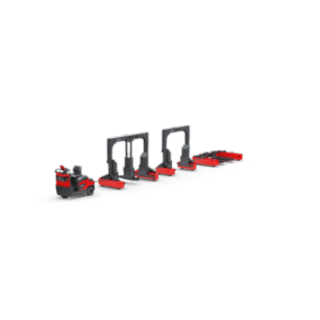

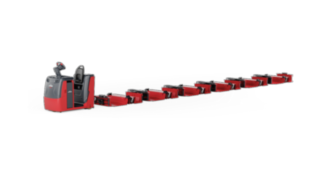

The LT10 – LT20 C / LT10 – LT16 B/BM tugger train trailers offer maximum versatility and flexibility. They can be used both indoors and outdoors and are the ideal solution for quickly transporting material between different halls. The robust two-axle design of the frame trailers makes it possible to transport larger loads. All-wheel steering ensures excellent directional stability and makes the LT10 – LT20 C / LT10 – LT16 B/BM the ideal solution in tight spaces. The modular concept means that different load carriers can be transported in one tugger train. Available with a C-frame (LT10 – LT20), B-frame and BM-frame (as LT10 – LT16) with adjustable middle support, you can increase the number of trolleys transported without significantly increasing the overall length of the trailer. The 2-step swing trailer lifting mechanism integrated in this series allows for reliable lifting and handling, even with individual customer racks. The frames are equipped with an electric lifting mechanism and a standardised interface, making them easy to automate.

Characteristics

Safety

The automatic start interlock on the LT10 – LT20 C / LT10 – LT16 B/BM prevents the tugger train from moving with the loading frame lowered and the trailer lowering mechanism is also deactivated while the train is in motion to prevent accidents. Each loading frame has load locking to hold the load securely in place. The electric lifting function maximises operating safety and ensures quiet operation while a special fork stabiliser also prevents the fork arms from sagging under high loads. Abrasion-free PU wheels are available for indoor use. When used outdoors, fully sprung and robust super-elastic wheels (SE wheels) ensure the vehicle travels safely, even on uneven ground. Various equipment options are available for special applications, including weather protection tarpaulins and different types of lighting.

- Immobiliser when loading frames are lowered

- Deactivated lowering mechanism while operating

- Load locking for secure hold

- Quiet electric lifting mechanism for operating safety

- Abrasion-free wheels for use in halls, SE wheels for outdoor use

Ergonomics

The frames can be quickly and easily connected to the towing vehicle using the plug-and-play principle. They lock automatically once the load carriers have been inserted, which significantly reduces the operating effort. The unlocking device is located at an ergonomic height and can be conveniently operated by foot to minimise the strain on the operator. As soon as the operator releases the locking mechanism of the C-frame (LT10 — LT20), a handy ejection mechanism gently pushes the trolley being transported out of the holder for efficient loading and unloading.

- Plug-and-play trailer coupling

- Automatic loading frame locking

- Easy to unlock by foot

- C-frame with handy ejection mechanism

Handling

The LT10 – LT20 C / LT10 – LT16 B/BM are equipped with a user-friendly touchscreen display that enables intuitive control and monitoring of the loading frames. The trailers’ all-wheel steering means that the entire tugger train is extremely manoeuvrable, making it easy to navigate through narrow areas. The automatic raising and lowering of the loading frames is particularly time-saving. As soon as the operator gets into the towing vehicle, the frames are raised automatically. When they exit the towing vehicle, these are lowered again. The trailers with B and BM frames (LT10 – LT16), which can be loaded and unloaded from both sides, provide maximum flexibility for goods handling. A standard interface for industrial automation ensures that the LT10 – LT20 C / LT10 – LT16 B/BM can also be used without an operator.

- Touchscreen display for controlling and monitoring the frames

- All-wheel steering for optimum manoeuvrability

- Load frame lifts and lowers automatically

- B and BM frames with loading and unloading on both sides

- Interface for automation

Service

The completely maintenance-free loading frame lift motors help to keep the total amount of maintenance required for the LT10 – LT20 C / LT10 – LT16 B/BM to a minimum. The two-axle design of the trailers also makes service technicians’ work easier. Any errors are shown on the touchscreen display, reducing the time required for troubleshooting. The coupling system and tiller are also almost wear-free to avoid unnecessary service costs. The service intervals of the loading frames and towing vehicle are synchronized to ensure efficient maintenance schedules and the least possible interruption to transport operations. On request, all trailers can be remote-controlled and equipped with an hour counter for precise usage documentation.

- Maintenance-free lift motors

- Simultaneous maintenance for trailers and towing vehicle

- Easy access for quick servicing

- Optional hour counter for each frame

- Error code display on the touchscreen display

Videos & Images

Technical Data

| Model | Load capacity/Load | Lift | Lift function | Overall length | Overall width |

|---|---|---|---|---|---|

| LT10-B | 1.0 (t) | 60 / 50 (mm) | Electric | 4050 / 2950 (mm) | 1470 (mm) |

| LT10-BM | 1.0 (t) | 60 / 50 (mm) | Electric | 4350 / 3250 (mm) | 1470 (mm) |

| LT16-BM | 1.6 (t) | 60 / 50 (mm) | Electric | 4350 / 3250 (mm) | 1470 (mm) |

Optional Equipment

-

Frame opening direction

-

Middle support

-

SE wheels

-

Lift heights

-

Rear lights

-

Rotating beacon

-

Weather protection

-

Push-through option for B-Frame

-

Load carriers

Frame opening direction

The standard opening side of the C-Frames is the right side. Optionally, the left side in the driving direction can also be chosen for a load exchange.

Middle support

The Bridge-Frame can be equipped with a flexible middle support (LT10 – LT16 BM), which can be moved to the required position so that different load sizes can be handled with one frame type.

SE wheels

For outdoor applications, the frames can be equipped with robust super elastic (SE) wheels with a diameter of 250 mm and a width of 85 mm or 130 mm. These wheels are equipped with additional suspension and dampen vibrations.

Lift heights

The standard lift height of 50 mm is sufficient for most indoor applications. For outdoor usage, the B and BM-frames can be equipped with an increased lift height of 80 mm and the C-frames with an increased lift height of 100 mm. Further lift heights are available on request.

Rear lights

There is a four-function LED rear light set with magnetic holder and two lights (indicator, rear lights, brake lights, licence plate light) available in clear glass. It provides sealed waterproof housing, e4 marking and assignment according to ISO 1724.

Rotating beacon

A flashing light can be fitted to the top of the trailer in order to make the tugger train visible in dark areas.

Weather protection

A tarpaulin roof, which can be pulled over the frame, is available for the C, B and BM-frames. It can be opened on one side for the C frame and on both sides for the B and BM frames.

Push-through option for B-Frame

With the standard lock, the load can only be pulled out in the direction of the operator. With the push-through option, the trolley can be pushed out through the frame in both directions, making heavy loads easier to handle for the operator.

Load carriers

Linde has a range of trolley designs for a wide variety of loads for all tugger train models. They can be equipped with modular racking superstructures, for example.

Get a Quote