Minimise door damage with Linde Door Control

Intelligent door control

In intralogistics, goods are often transferred between indoor and outdoor areas, between different halls as well as within the same hall. In order to make this flow of materials as efficient as possible, operators usually use high-speed doors. Their rapid opening and closing speeds ensure short waiting times. At the same time, the closed door systems ensure constant temperatures in production and logistics halls, protect employees from draft-related illnesses, stop birds from entering and prevent contamination.

However, there are frequent incidents involving the doors, some of which are industrial truck-related. A typical example is a collision where the high-speed door is not fully open at the time of passage. Although this usually only results in material damage, the costs of repairs to doors, forklift trucks and goods can add up to considerable amounts.

Operators often find themselves under time pressure or their thoughts may be elsewhere and they briefly fail to pay attention. With Linde Door Control,our customers can now effectively reduce risks in this accident-prone area, thereby avoiding costs and disruptions to operations.

Fabian Zimmermann, Product Manager for Safety Solutions at Linde Material Handling

All-round safety in intralogistics

Linde Door Control is an addition to the Linde Safety Guard all-round assistance system. In addition to providing door protection, this system is designed to protect against all potentially hazardous situations that can arise when industrial trucks and people interact in complex surroundings, making it difficult to have an overview of the whole area. The modular solutions are perfectly aligned to provide comprehensive protection for warehouses and production halls. This guards against risks, saves costs and gives employees an all-around feeling of safety at work.

Increasing safety and reducing costs

These expensive mishaps are now a thing of the past: wherever high-speed doors are installed in production plants and goods distribution centres, users can use the Door Control module offered as part of Linde Material Handling’s innovativeLinde Safety Guardassistance system. The intelligent door control system ensures continuous and reliable communication between industrial trucks and the infrastructure. This allows the speed of approaching forklift trucks to be reduced if necessary. Safety when navigating through doors is increased as a result, saving on repair costs that result from collision damage. It also means that the doors close more quickly, which, for example, reduces energy losses, and saves on additional costs in turn.

This is how the intelligent door control works

As part of the Linde Safety Guard assistance system, Linde Door Control is based on ultra-wideband technology (UWB). The forklift truck communicates with the building’s infrastructure via high-frequency radio waves. When a forklift truck approaches a high-speed door, it gradually decelerates while the door is opening automatically. For this to happen, the system determines the distance between the fixed units on the forklift truck and the door to within ten centimetres. Once through, the high-speed door closes and the forklift operator can continue travelling at a normal speed.

More safety thanks to individual solutions

Made-to-measure safety zones

Linde Door Control accurately coordinates the speed of the forklift truck with the opening mechanism of the high-speed door. This allows the size and shape of the zones to be set according to the user’s requirements so as to prevent the door opening mechanism from being triggered by passing forklift trucks or to prevent neighbouring doors from opening. Regardless of whether single or multiple high-speed doors are involved, Linde will provide the perfect control solution.

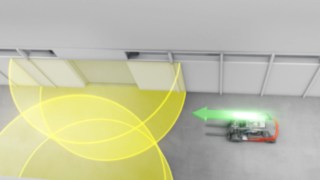

For individual doors: Door Control Circle

In the case of an individual door, the 'Circle' module is used to create a circular safety zone around the door. When the forklift truck approaches and enters the yellow zone, its speed is automatically reduced, for example to 6 km/h. Once it reaches the red zone directly in front of the door, the speed is reduced again, for example to 2 km/h. Both zones and the associated speeds can be customised to suit the specific operation. At the same time as the speed is reduced, an opening signal is sent to the door. As soon as the door is open, the red zone is deactivated and the forklift truck can accelerate again to the speed of the yellow zone (here: 6 km/h) to be able to navigate through the door. Once it has moved further away and also exited the yellow zone, it can immediately accelerate back to normal speed.

For multiple doors: Door Control Rectangular

The 'Rectangular' solution by Linde Door Control is used for neighbouring doors. It ensures that only the high-speed door which is being controlled at that moment opens, while the other doors in the vicinity remain closed. The speed of the forklift truck is reduced in exactly the same way as with the 'Circular' version. Both versions can be supplemented with an optional warning projector. This can be used to warn pedestrians crossing the doorway on the other side. The warning is activated at the same time as the door control so that pedestrians can stop or leave the doorway in good time.

Your benefits at a glance

Linde Door Control in use at the SCHERM Group

The SCHERM Group is an international system service provider in the areas of transport, real estate and logistics. At the Ingolstadt site, every day more than 200 trucks and 55 forklift trucks pass through the central goods receiving area with its multiple adjacent rolling doors. With so much traffic the risk of collisions increases, which can quickly drive up the cost of repairs. Linde Door Control’s 'Rectangular' solution enables precise communication between the truck and the building. It ensures that the truck speed is reduced automatically, enabling the door to be fully opened when the truck passes through with goods stacked high.