The requirements for industrial trucks are as individual as the companies that use them. In particular, start-ups, companies in their growth phase or with varying operating times looking for opportunities to meet their specific requirements both reliably and economically. Linde Certified used forklifts are a high-quality and cost-effective alternative. The trucks are also a logical addition for companies with larger fleets of forklifts, if the aim is to provide an appropriate mix of new equipment and Certified used forklifts to meet various requirements and applications.

Linde Material Handling has developed a high-quality, reliable solution for these requirements. For this purpose, used forklifts from Linde undergo a standardised remanufacturing process. This ensures that the forklifts meet the necessary quality standard for the requirements and areas of application in question.

Seamless service history and standardised reconditioning

The used forklifts in the 'Certified Trucks' programme are essentially selected returns from Linde's own short term and long term rental fleets. These forklifts were regularly serviced by Linde service technicians during their initial use. The seamless truck and service history and careful inspection when the forklift is returned mean that Linde only selects the very best equipment for the 'Certified Trucks' program.

This equipment is then remanufactured based on one of the three standards, PLUS, SUPER, or ULTRA and labelled with the 'Certified by Linde' seal of quality. This quality seal is a national standard, which guarantees that the Certified used forklifts supplied by Linde always comply with the same high performance requirements. This ensures that buyers can always rely on the same high product quality wherever they buy a Certified used forklift from Linde.

Reconditioned Forklifts With A Seal of Quality

At Linde, used equipment is remanufactured on the basis of a standardised process. Specially trained Linde technicians diligently work through the remanufacturing process in specialised regional reconditioning centres or at selected local Linde service locations. If a part needs to be replaced, the technician only ever installs durable Linde original spare parts. Only once a used forklift has successfully passed through the entire process does it receive the 'Certified Truck' seal of quality. To break it down, the process consists of the following steps:

For the refurbishment process each truck is cleaned thoroughly

For the refurbishment process each truck is cleaned thoroughly

1. Ex-Rental Trucks:

Linde Certified Trucks are typically ex-rental trucks, maintained from new by Linde engineers.

2. Comprehensive Inspection: A qualified engineer carries out a meticulous examination to identify areas of the used forklift and components requiring attention.

3. Remanufacturing process:

Components are either repaired or replaced - only genuine Linde parts are used in the remanufacturing process.

During the inspection all data of the used truck are checked

During the inspection all data of the used truck are checked

4. Engine check and emissions test: On engine powered trucks, to ensure complete operational reliability and compliance with exhaust emission regulations, the engine undergoes stringent testing using the most up to date diagnostic equipment.

5. Battery and charger:

On electric used forklifts the battery is checked to ensure serviceability, and cells replaced where necessary.

The trucks are refurbished down to the last detail

The trucks are refurbished down to the last detail

6. Pressure washing:

Each used forklift is thoroughly steam cleaned to remove all accumulated dirt and grime prior to inspection.

7. Refresh/Repaint:

All used forklifts are repainted to ensure a quality finish, prior to new decals and the Certified Truck identification plate being fitted.

8. Pre-delivery check: The final procedure is an independent multipoint check including chain and fork certification. A legal control certificate will be provided with every machine.

Reconditioning standards for every requirement

Linde provides Certified used forklifts in three standards of Linde PLUS, SUPER and ULTRA. The main differences between them are the level to which the forklift truck is reconditioned and the warranty period. This means that you as the customer can choose the right truck for your individual operating conditions and requirements.

Linde PLUS used forklifts are ideal for applications with a lower workload. The Linde SUPER category is generally suitable for medium workloads. Linde ULTRA is the right category for demanding applications with a higher workload. However, the optimum remanufacturing standard for your requirements depends on a number of factors. That's why your Linde sales partner is on hand to provide extensive advice to help you make the right choice. The following provides an initial overview of the details and the differences between Linde PLUS, SUPER and ULTRA.

Linde PLUS

The Linde PLUS standard includes the following remanufacturing measures and equipment features:

- Used forklift serviced and tested in accordance with the manufacturer‘s recommendations

- Mast, fork carriage and hydraulic system tested in accordance with the manufacturer‘s specifications

- Emissions test

- Battery charger functional and PAT test conducted

- Battery in working order in electric forklifts

- Safety of steering axle checked

- Serviceable tyres with at least 30 percent tread depth

- Functional electric motor

- Full functionality based on the local standards

- Paintwork refreshed to manufacturer's original colours & replace decals if needed

- Tested drive unit

- Usable operator‘s seat and safety belt

- Lift chains fully functional and tested in line with LOLER regulations

- Maximum wear 2.4 percent

- Forks fully compliant with LOLER regulations

- Operating hours counter checked

- Operating instructions

Market leading warranty options available – see below

Linde SUPER

The Linde SUPER standard includes the Linde PLUS features mentioned above as well as the following points:

- Emissions test and compression pressure measurement for IC trucks

- Battery capacity of more than 70 percent

- Battery charger functional and PAT test conducted

- Steering axle checked in accordance with the manufacturer‘s specifications

- Serviceable tyres with more than 60 percent tread depth

- Hydrostatic unit or combi-axle checked in accordance with the manufacturer‘s recommendations

- Re-painting in original Linde colours and Linde labels

- Well-maintained operator‘s seat and safety belt

- Forks fully compliant with LOLER regulations with greater than 60 percent wear life remaining

- Lift chains fully functional and tested in line with LOLER regulations. Maximum wear 1.8 percent

- Transparent truck history

Market leading warranty options available – see below

Linde ULTRA

Approved used forklifts in the Linde ULTRA category have the same features as Linde SUPER together with the following additional features:

- Overhauled combustion engine

- Overhauled electric motor

- Battery charger refurbished, tested and certified or new charger

- New battery or less than three years old with at least 80 percent capacity

- Completely overhauled steering axle

- New set of tyres or serviceable with at least 90 percent tread depth

- Flawless visual condition with full re-painting

- Operator‘s seat and safety belt as new

- New forks or forks fully complaint with LOLER regulations with 90 percent wear life remaining

- New lift chains or fully functional and tested in line with LOLER regulations. Maximum 0.3 percent wear

- Bearings in the mast checked and replaced where necessary

- Control elements new or as new

Market leading warranty options available – see below

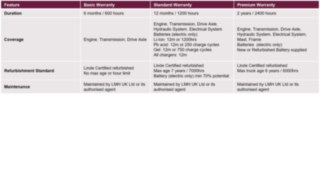

Warranty options

A reliable all-round package

Benefits of the 'Certified Trucks' programme at a glance:

Certified used forklifts are not just an alternative, but rather the first choice for certain companies. Certified used forklifts offer relevant benefits depending on the specific requirements for the respective company phase or the composition of the existing fleet. These include:

Quality:

- Careful, standardised remanufacturing process for the Certified used forklifts, including parts replacement exclusively with new original Linde spare parts.

- The entire Linde product range in 'Certified Trucks' quality: from hand pallet trucks to high-performance forklifts.

- Certification in accordance with the latest statutory requirements and EU guidelines.

Choice:

- Three standards to suit a broad range of individual customer requirements with regard to cost-effectiveness and operating conditions: PLUS, SUPER and ULTRA.

- Available from a location near you.

- Large choice of accessories.

Service:

- Various financing and service packages, such as long term rental with full-service contract.

- Quick and comprehensive service directly at the customer's location.

- Training opportunities for operators or forklift license test.

- Test drive possible at any time.

The wide selection of Certified used forklifts within the Linde network ensures that we can always find the right truck tailored to a specific application and budget.